FORGING

FORGING

SQuAD Forging India is a joint venture between Aequs and Aubert & Duval, a global player in large closed-die forgings. The JV manufactures aerospace parts and components of the highest quality and reliability for aerospace OEMs and other global customers.

The aerospace industry requires forged parts of the highest quality to meet industry standards of reliability and durability.

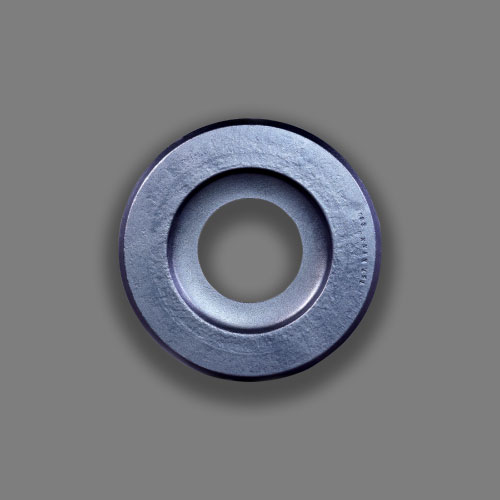

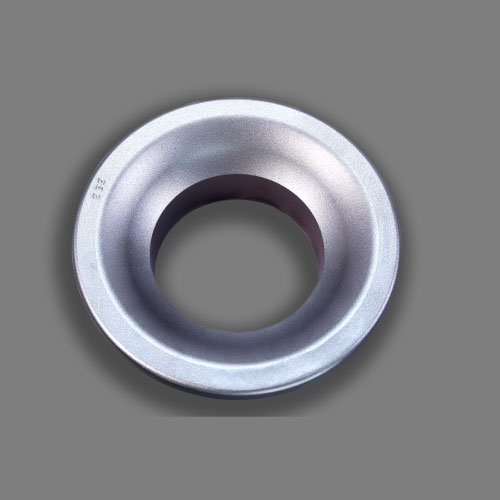

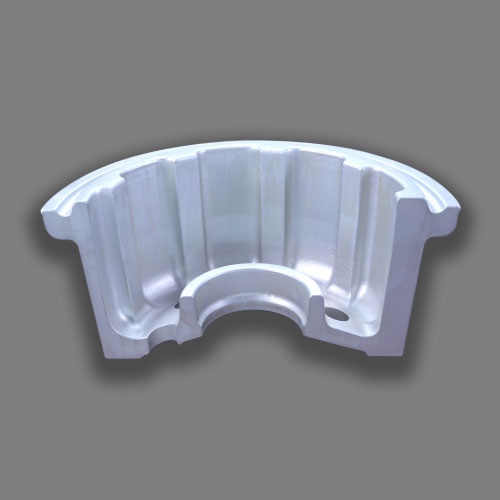

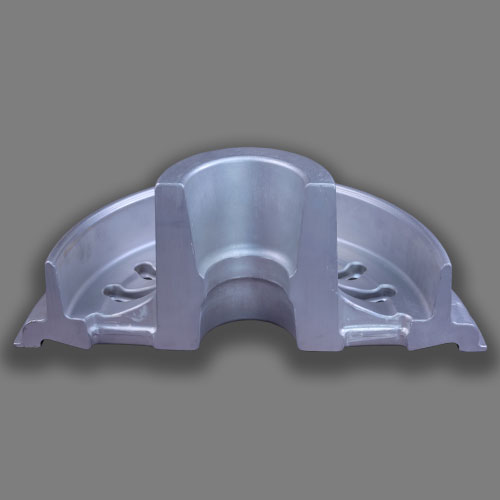

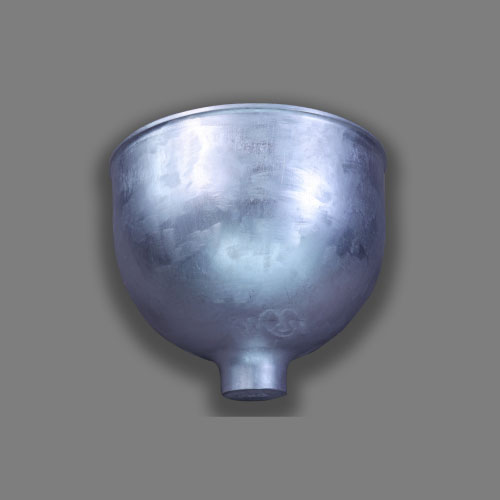

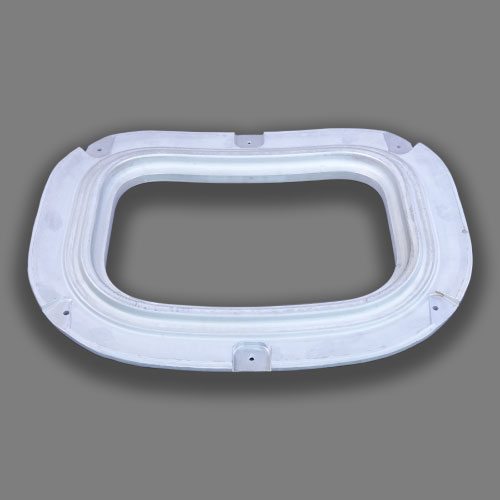

SQuAD Forging specializes in the forging of small to medium-sized aerospace parts for engines, landing gear, and braking system components in Aluminium, Steel, Titanium, or Nickel-based alloys. SQuAD has the capability to forge highly critical components for the Aerospace, Power Generation, and Oil & Gas industries.

The state-of-the-art unit is well equipped with separate forging lines of 10,000T Hydraulic Press, 1200T Screw Press and all associated heat treatment dedicated lines. SQuAD also has an inspection and testing facilities with a well-equipped laboratory.

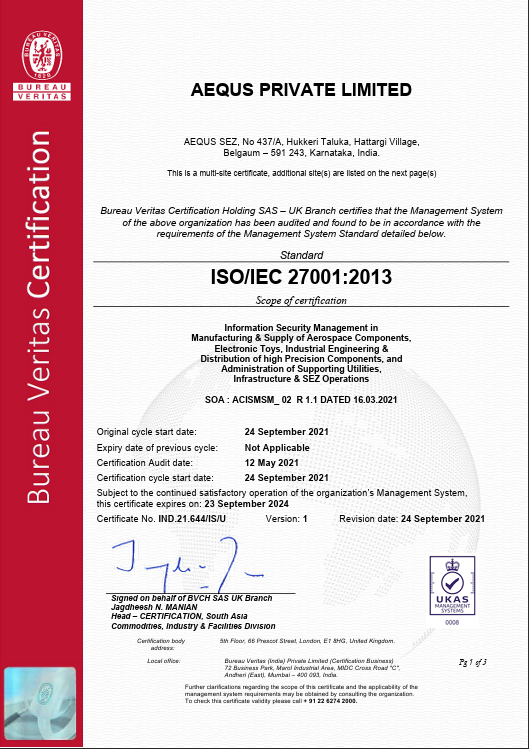

SQuAD is approved by global OEMs and certified with ISO 9001, AS9100, ISO 27001, ISO 14001 and ISO 45001, while the Heat Treatment, and NDT-UT are NADCAP certified.

India’s Largest Hydraulic press- 10K ton

Heat treat approved by Safran

- Closed-die forged parts

- Hydraulic Press: 10KT for Ti/St/Al

- Screw Forge: 1200T

- NADCAP qualified Heat Treatment & NDT-UT

- Finishing & Etching , Inspection of forgings

- Lab for Metallurgical testing

Our Capabilities

-

- 10,000T Hydraulic Press

- Billet Heating Furnaces: Aluminium

- Temp range: 300 to 550°C

- Class 3 (+/-7°C) as per AMS2750

- Billet Heating Furnace: Steel, Titanium, Superalloys

- Temp range: 820 to 1250°C

- Class 4 as per AMS2750 (+/-10°C)

- 10,000T Hydraulic Press

-

- Forging press- 1,200T Screw Press

- Billet Heating Furnace: Aluminium

- Temp range: 300 to 550°C

- Class 3 (+/-7°C) as per AMS2750

- Billet Heating Furnace: Steel & Titanium

- Temp range: 800 to 1250°C

- Class 4 as per AMS2750 (+/-10°C)

- Forging press- 1,200T Screw Press

-

- Heat Treatment Line- Aluminum

- Furnaces complying with AMS 2750

- Aluminium Solutionizing: 1100 Kgs / Batch

- Temperature range from 90 to 550°C

- Class 1 (+/-3°C) & Class 2 (+/-5°C)

- Aluminium ageing: 4000 Kgs/ Batch

- Electrical heating

- Temperature range from 70 to 220°C

- Class 1 (+/-3°C)

- NADCAP & Customer Approved Facility

- Heat Treatment Line- Aluminum

-

- Heat Treatment- Steel & Titanium

- Furnace complying with AMS 2750

- Capacity: 1000 Kgs/ Batch

- Solutionizing: 750-1160°C, Class 4 (+/- 10°C)

- Tempering: 350-750°C, Class 2 (+/-5°C)

- NADCAP & Customer Approved Facility

- Heat Treatment- Steel & Titanium

Our Processes

-

- Laboratory

- Hardness testing

- Tensile testing

- Micro-structure

- Electrical Conductivity

- Laboratory

-

- Heat Treatment

- Solutionizing

- Ageing

- Quenching

- Tempering

- Heat Treatment

-

- NDT

- UT contact type

- NDT

-

- Dedicated Team with

- SAP ERP

- Customs office for material clearance

- International logistics contract in place

- Closed-die Forging

- 10K T Hydraulic Press

- 1200 T Screw Press

- Dedicated Team with