AEROSTRUCTURE ASSEMBLIES

AEROSTRUCTURE ASSEMBLIES

Aequs is the first company in India to assemble Plug Doors and Over-Wing Exit Doors for commercial aircraft OEMs through its unit, the Aerostructures Assemblies India (AAI). It offers build-to-print assembly and design-to-print solutions for commercial and space programs.

A part of the Aerospace ecosystem, AAI delivers Build-to-Print (BTP), assembly solutions for the industry.

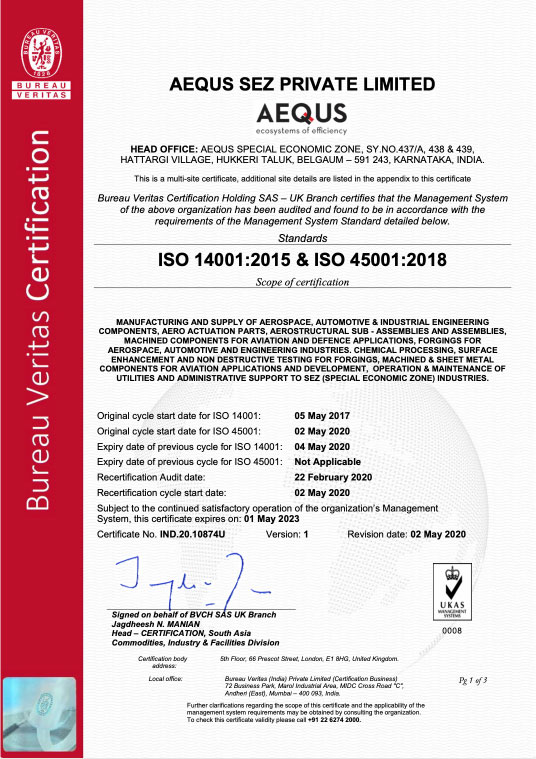

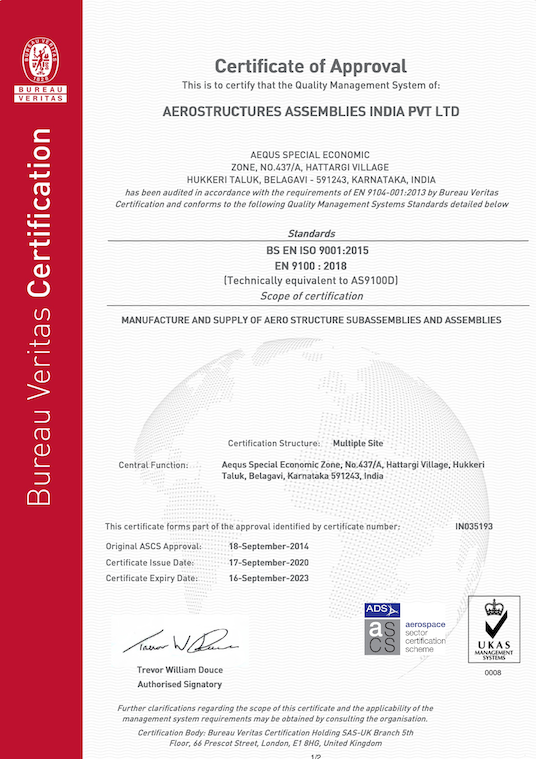

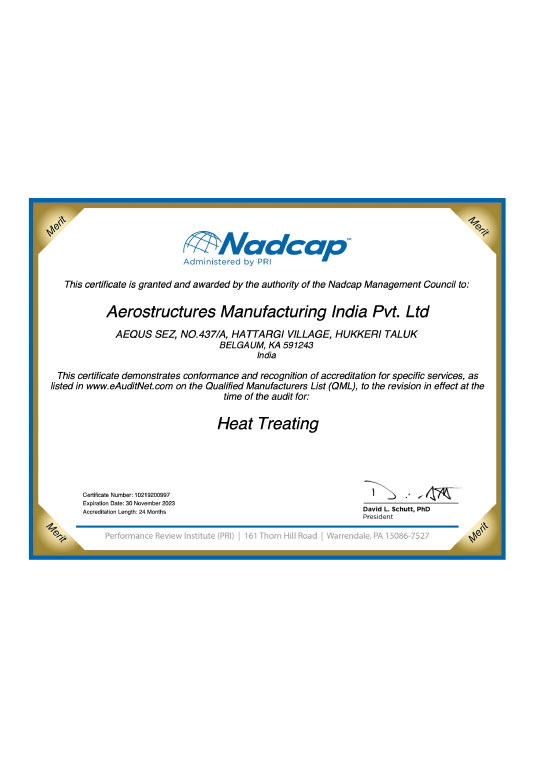

It has all requisite certifications, including GRAMS, AS9100, OHSAS, and qualifications from key customers, including AIPI (Airbus, Germany) & ABP (Airbus, UK) for assembly processes, Aequs fosters agile industrialization and delivers superior customer value.

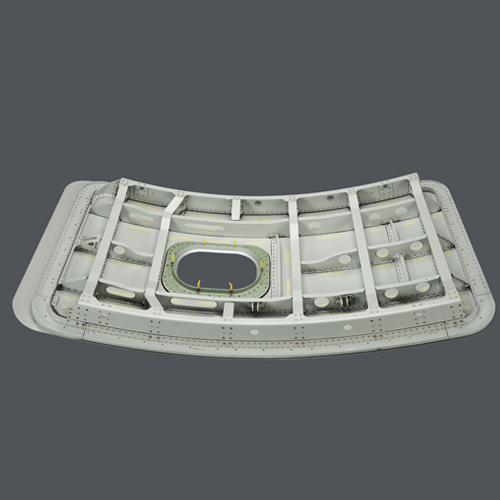

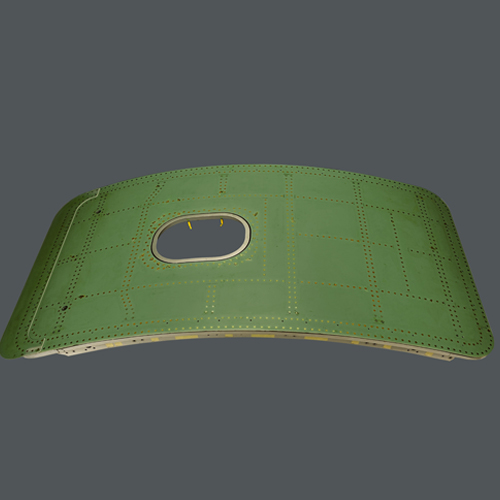

First in India to Assemble Plug Door & Over-Wing Exit Door

-

- Structural assemblies for wing & fuselage (A380, A320)

- Sole source for Over-wing Exit & Plug Door Assemblies (A321 NEO)

- Assembly Tooling (Fixtures, Jigs)

- Domestic Space programs (ISRO)

Commercial Aircraft Programs

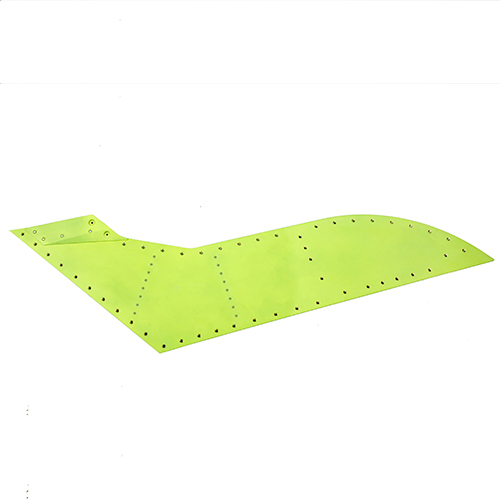

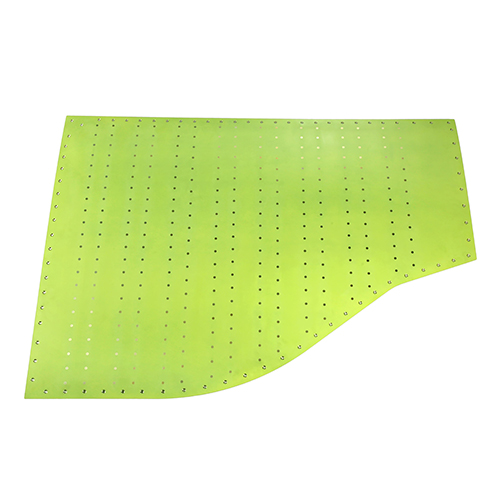

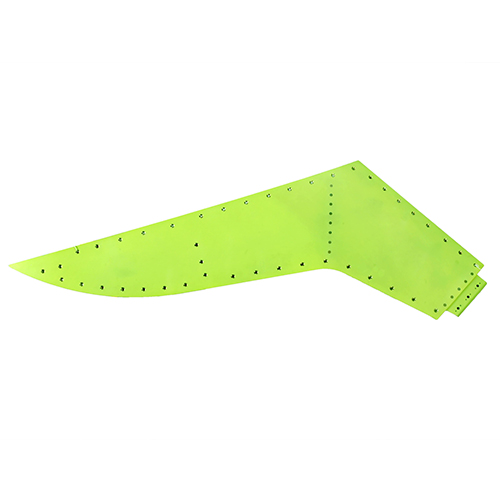

We specialize in Build to Print assemblies for Door-3-Plug (D3P) and Over Wing Exit Door (OWED) structures (~ 2 meters long, weighing under 100 kgs) of the Airbus A321 Neo program. While we commenced our journey with Wing leading edge and Wing panel assemblies for the A380 program, we have consistently demonstrated maturity in accomplishing complex assembly of Door-3-Plug and strikingly rapid industrialization for high build rate OWED assembly line.

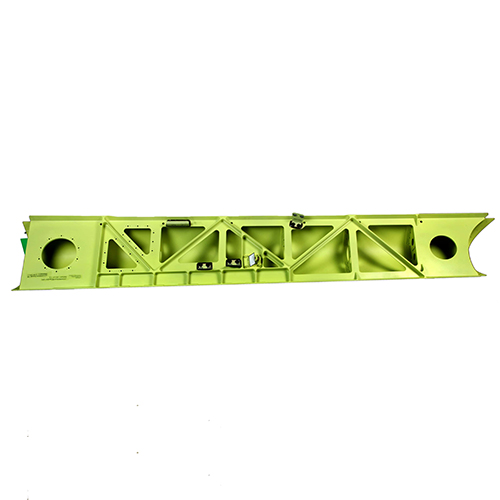

Space Programs

Making our mark in India’s space program, we have built capabilities ranging from panel sub-assembly to larger size integrated assembly structures for space launch vehicles. We manufacture Nose cones, Aerodynamics Stabilizers for the PSLV program (Polar Satellite Launch Vehicle) and inter-stage assemblies and thrust frames for GSLV (Geosynchronous Satellite Launch Vehicle) program operated by the Indian Space Research Organization (ISRO). Besides manufacturing end products, we also design and manufactures jigs and fixtures for related assemblies.

Our Capabilities

-

- Build to Print Solutions

- Precision drilling

- Single Pass drill-ream CSK (Semi-automated drilling)

- Application of fay and fillet sealing

- Electrical bonding

- Installation of pre-designated torqued fasteners

- Installation of blind fasteners

- Riveting

- Anti-gravity mechanism for an ergonomic working environment

- The standardized kit supply system

- Direct line Feed for BOI’s (DLF)

- Build to Print Solutions

-

- Interchangeable Assemblies

- Lieca Laser Tracker

- Gauge R&R (approved from Airbus)

- Interchangeable Assemblies

-

- QMS

- Documentation Control

- Quality Clinic: KPI, RCCA

- APQP (Advanced Product Quality Planning) & PPAP (Production Part Approval Process) Airbus approved.

- Value stream mapping -Lean initiatives

- Continuous improvement

- QMS

-

- Robust Supply Chain

- Global network

- Supplier Evaluation

- Planning, review & monitoring

- Robust Supply Chain

-

- Tooling-Calibration

- Using PCDIMS Program

- Controlled environment

- CMM for Small Jigs

- Tooling-Calibration

-

- ERP System

- Process Management: SAP 4HANA

- Material Planning

- ERP System

-

- Packing & freight forwarding

- Airbus approved packing standards

- Logistics for export dispatch

- Packing & freight forwarding

-

- Training

- A structured program for engineers & operators-Project specific

- Refresher and re-training modules based on product quality review

- Dedicated induction training program highlighting company goal and objectives

- Training